Applying the Four Dimensions of Sustainability to Create Capacity That Delivers Results Faster

Applying the Four Dimensions of Sustainability to Create Capacity That Delivers Results Faster

This is the first in a series of articles on applying the four dimensions of sustainability to pharmaceutical research, development, and manufacturing operations.

Developing and growing outstanding organizations is a passion of mine. I have spent much of my professional career leading, transforming, and growing life sciences organizations cutting across medical device, API manufacturing, contract research organizations and pharmaceutical/biotechnology research, development, and manufacturing operations. Experience has taught me there are no shortcuts to growing capacity that delivers results faster and maintaining it is difficult. The key ingredient in growing enterprise value is sustainability.

When we encounter the term sustainability, we often think about the actions, policies, and behaviors intended to preserve our natural resources: air, water, and land. I greatly praise these efforts, but I think this definition is too narrow.

Reimagining the Desired Outcome of Sustainability

Let us begin by reimagining and redefining a desired outcome to be achieved from sustainability. What if the outcome of sustainability is capacity?

Capacity, like sustainability, is also often too narrowly defined. Afterall, capacity is both the ability to produce as well as to contain or hold something. For pharmaceutical operations, when setting out to grow capacity, we must consider not only the means we have to make drug products, but also the capabilities we possess.

Operational capacity is something we can define, develop, and measure. A pharmaceutical contract development and manufacturing organization (CDMO) seeking to grow capacity often considers adding facilities, development labs, manufacturing suites, and packaging lines. Desired capacity is either constructed or purchased from someone else. However, by applying the principle of sustainability, capacity can be grown using existing resources, lead time for customer success is improved, and most importantly, patients receive more effective treatments sooner.

Consider our common understanding of sustainability as applied to natural resources. Natural resources are not the only finite resources in our world. When I consider the resources employed to conduct pharmaceutical development and manufacturing operations, none of them are infinite. Think about the following list of precious, finite resources, each of them critical to our operations at Pii.

- Energy—lighting, heating & cooling, power for equipment, labs, and manufacturing suites.

- Human Resources—safety, wellness, experience, skill alignment.

- Facilities and Physical Space.

- Leadership.

- Time—lead time, the precious period between beginning concept development to beginning production.

When conservation of these resources is pursued separately, a fragmented set of outcomes can be achieved at best. However, when they are placed together in a sustainability model, amazing outcomes can be realized. I have discovered that pursuing sustainability using an integrating model results in capacity growth as well as a speedier path to results for pharmaceutical operations.

Dimensions of Sustainability

Pharmaceutical operations are typically organized by a common set of functional areas, e.g. research and development, process design, manufacturing, quality, regulatory, and packaging. We further create departments responsible for these functions, we assign skilled people to them, and we resource them with the facilities and equipment needed to perform their duties.

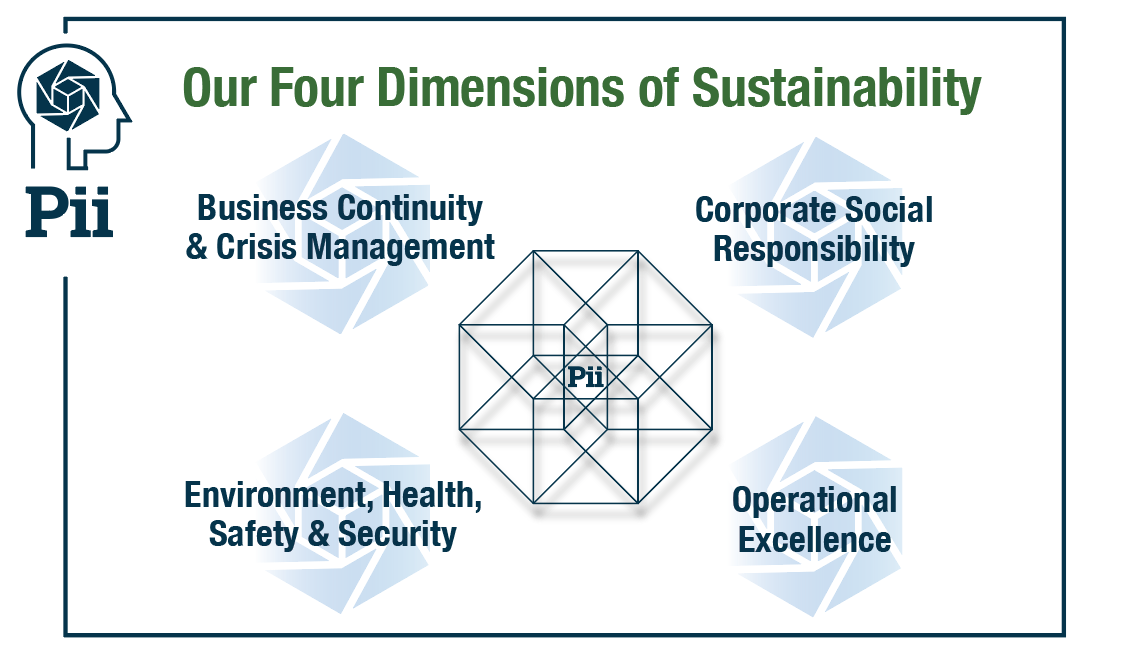

I am not suggesting we abandon this model, but when I consider a sustainability model, I envision four dimensions.

• Environmental, Health, Safety and Security

• Business Continuity and Crisis Management

• Corporate Social Responsibility

• Operational Excellence

I choose to refer to the components of this sustainability model as dimensions, but they can also be described as visionary objectives, strategic goals, or situational conditions. For example, my goal for the first dimension at Pii is a work environment that is healthy, safe, and secure for our employees, customers, visitors, products, the patients that will use the products, the equipment we need, the business park and campus around us, etc. However, a dimensions model enables holistic capacity growth: the ability for sustained production of pharmaceuticals.

I can further define what a healthy, safe, and secure environment means. Specific goals can be established within the context of each dimension for each of the finite resources critical to operations. There is also an interdependent relationship among the dimensions and the resources.

For example, due to an increasing number of customer projects we may determine we need more capacity, but we do not have enough time, one of the finite resources, to build or buy it. We decide to conduct 24-hour continuous operations. In developing a plan, our dimensions model calls for us to consider the safety of the parking area and entrance to the building for employees arriving and leaving during the hours of darkness. We must also monitor the wellness of workers who are suddenly working at night. As we refine our 24-hour operations we will have successfully created additional capacity and reduced the amount of time required to deliver results to our customers. Each of the four dimensions requires similar considerations.

When CDMOs consider ways to grow capacity, they often think of investing in additional resources. However, when applying the principle of sustainability using its four dimensions, finite resources are more wisely used with extraordinary results, lead time from concept to commercialization is greatly improved, and patients receive better medications faster. We will be authoring more articles on sustainability, examining each of the four dimensions in more detail. Please look for them on our website or feel free to contact us directly for where to find them.

Talk to a Pii Scientist

ABOUT Pii

Pharmaceutics International, Inc. (Pii) is a US-based contract development and manufacturing organization (CDMO) located in Hunt Valley, Maryland. The experienced scientists, engineers, and staff at Pii pride themselves on adroitly employing a phase appropriate method of drug development for the prudent use of their customer’s resources as they solve challenging problems. In addition to offering end-to-end development services, Pii manufactures a variety of dosage forms to include complex parenteral drugs and has a wealth of analytical testing capabilities. Its Hunt Valley campus has four aseptic suites with lyophilization capabilities. Our talented professionals stand ready to help!