Contact Us

- Solutions

- Resources

- About

- Contact Us

close

Optional callout banner for highlighted news or events

Learn More

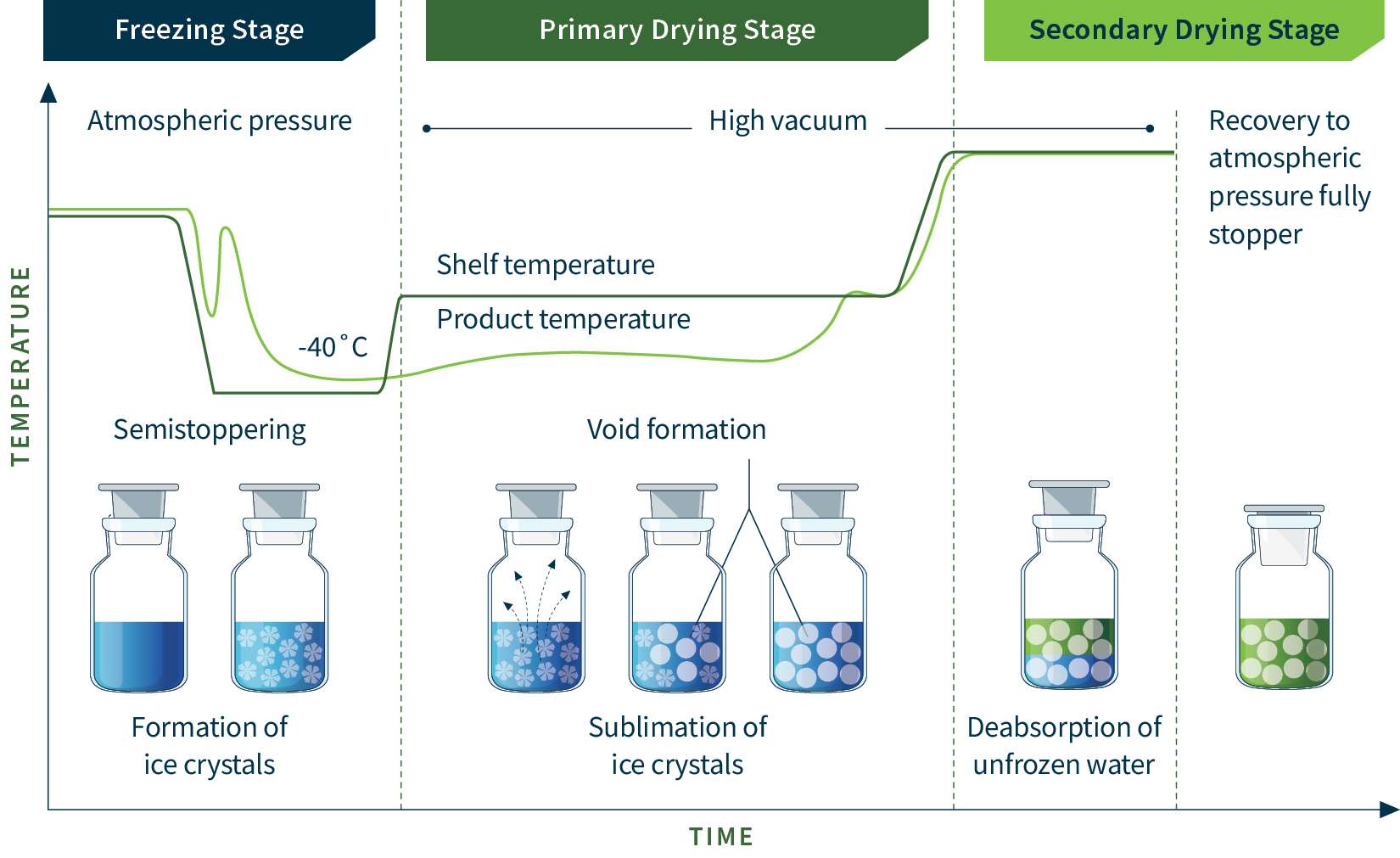

Custom lyophilization services and formulation development.

Expert-led lyophilization cycle development for success.

Clinical Trial Supply without the waste, providing 3mL to 50mL vials.

Commercial batch sizes up to 20k units.