Contact Us

- Solutions

- Resources

- About

- Contact Us

close

Optional callout banner for highlighted news or events

Learn More

In aseptic pharmaceutical manufacturing, getting sterility right is non-negotiable—but success involves more than cleanrooms and isolators. For drug developers evaluating contract development and manufacturing organizations (CDMOs), real differentiators are often found in people, process design, and digital controls.

Sterile injectable drugs continue to be one of the fastest-growing segments in pharma, from biologics to complex formulations. But rising regulatory expectations and manufacturing complexity raise the stakes. Choosing the right CDMO isn’t just about capacity—it’s about ensuring a partner can actively reduce risk, protect product quality, and help maintain regulatory compliance.

Here are the factors that pharma teams should prioritize when evaluating aseptic manufacturing partners:

Modern cleanrooms, isolators, and automated filling lines are industry standards. Yet regulatory bodies including the FDA and EMA increasingly focus on the human element—operator training, procedures, and risk management.

Even with state-of-the-art equipment, sterility depends on the people running it. CDMOs should have robust operator qualification programs in place. Comprehensive training in gowning, aseptic techniques, and contamination control should happen continuously—not just once during onboarding.

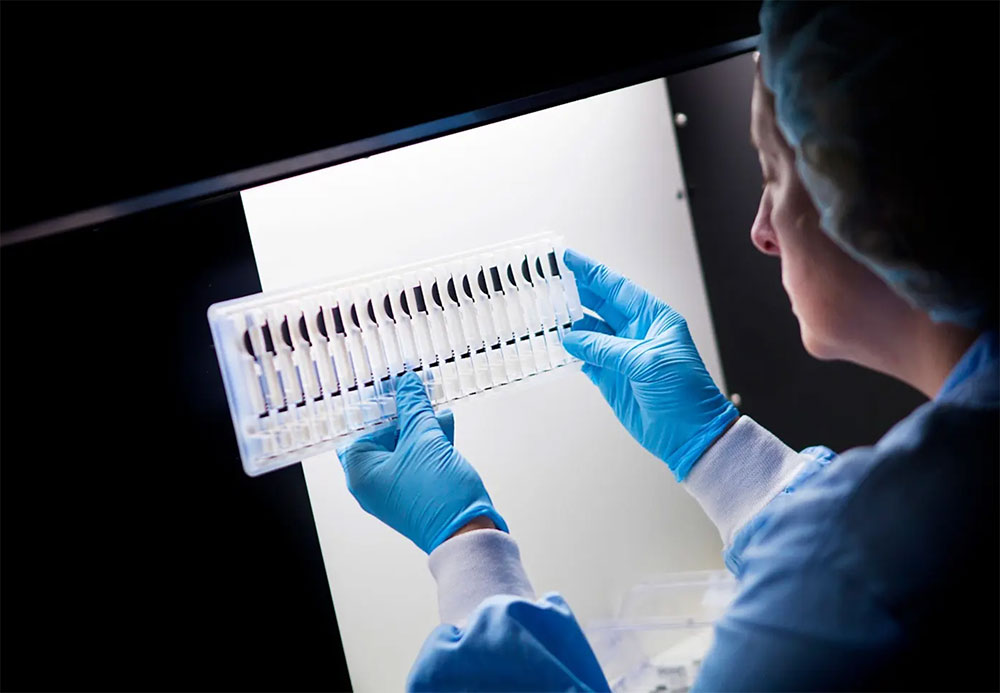

During audits, look beyond certifications. Strong partners conduct media fill simulations under real production conditions several times a year. This demonstrates true operational readiness, not just theoretical compliance.

A well-documented quality system is necessary, but it’s the organization’s culture that often determines whether issues are identified early—or overlooked until they become bigger problems.

Ask potential partners how quality issues are reported and resolved. Organizations where operators feel supported in flagging concerns tend to avoid more serious contamination events. Look for real-world examples of how deviations or contamination incidents have been handled. Transparency and a track record of learning from past challenges are strong indicators of reliability.

Human vigilance is critical, but in modern aseptic manufacturing, digital systems now play a central role. Paper-based records and manual monitoring leave too much room for error and delay.

Look for CDMOs that use electronic batch records (EBR), continuous environmental monitoring (EM), and data analytics platforms. These systems allow real-time detection of deviations and better trend analysis, reducing the likelihood of undetected contamination.

For complex injectable products, having access to comprehensive EM data and reporting isn’t just a nice-to-have—it can prevent costly batch loss or regulatory citations. Confirm that potential partners can provide full data review and transparent reporting.

In aseptic processing, facility layout and workflow are just as critical as cleanroom classification. Poorly designed spaces or traffic patterns can introduce contamination risks even with advanced equipment in place.

Evaluate whether a CDMO’s facility is set up with best practices in mind: clear separation between personnel and material flows, unidirectional movement, logically arranged cleanroom zones, and ergonomic process flows.

Rather than relying solely on facility tours, request layout diagrams and process flow maps. Consider bringing in third-party auditors to assess how closely the facility design aligns with industry benchmarks.

Sterile injectable manufacturing isn’t just about what happens on the fill line. CDMOs that can support everything from formulation development to packaging provide added value by reducing transfer risks and simplifying project management.

This is especially important for complex products such as biologics, liposomes, and high-viscosity drugs. Partners that offer integrated services—formulation development, sterile filtration, lyophilization, and device assembly—help reduce timelines and streamline oversight.

When choosing a CDMO for aseptic manufacturing, it’s easy to focus on facility tours, technology lists, and capacity numbers. But the full picture includes people, culture, and real-world performance.

Ask questions that dig deeper:

Pharma teams that take time to explore these areas are more likely to find a partner equipped not just to deliver sterile products, but to do so with consistency, reliability, and regulatory confidence.

Like what you read? Share with your network: