Contact Us

- Solutions

- Resources

- About

- Contact Us

close

Optional callout banner for highlighted news or events

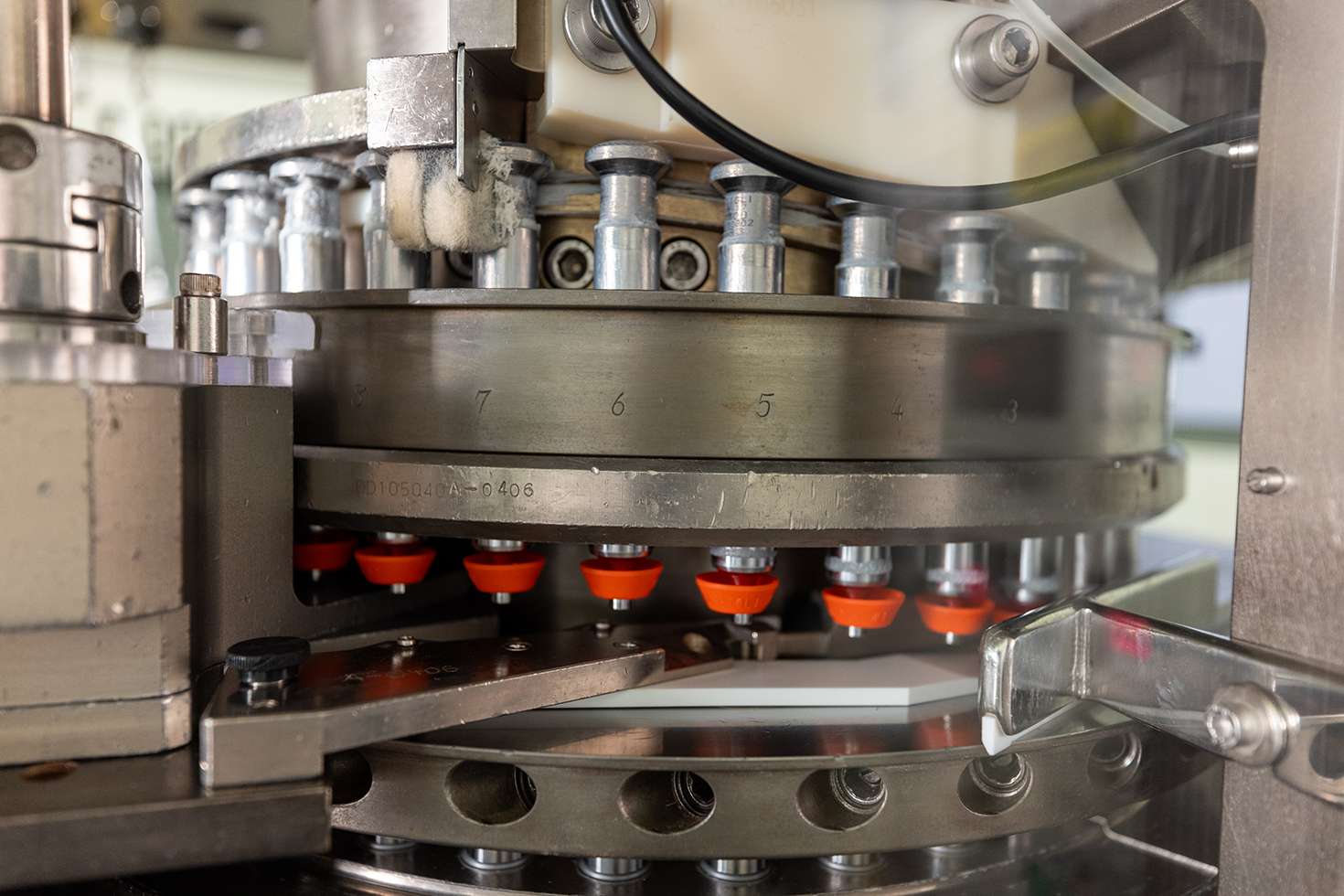

Learn MoreQuality is non-negotiable. Our unwavering commitment to exceeding cGMP requirements through continuous monitoring and process improvement enables us to meet tomorrow's challenges today.

Custom-engineered quality processes—because no two projects are the same.

Processes that work as hard as we do, optimized for peak efficiency. We know the stakes are too high for wasted time or effort.

Fix it fast, fix it for good. Every issue solved, every recurrence stopped in its tracks—because quality doesn’t compromise.

We don’t rest on “good enough.” Ongoing audits and inspections keep our standards high and your products on point.

Confidence built in. From cGMP to global standards, we deliver compliance you can count on at every phase.

Your project is in safe hands. Our integrated electronic quality management software (eQMS)—fully 21 CFR Part 11 and Annex 11 compliant—automates and streamlines quality management. The result? Uncompromising transparency, efficiency, and quality.

MasterControl

MasterControl puts you in control. From document and procedure management to training, this eQMS boosts efficiency with built-in safeguards for seamless process automation and optimization.

TrackWise

Track it all with TrackWise. From deviations to CAPAs, complaints to audits, this agile eQMS enables comprehensive quality oversight with precision, ensuring nothing slips through the cracks.

“We understand customer requirements and meet those in addition to FDA requirements—we go above and beyond simple compliance.”

Mitch Tse

Head of Quality

100%

FDA Licensed to Produce Commercial Products

4

cGMP Centers of Excellence

70+

GMP suites equipped for precision

2

FEIs for oral and aseptic manufacturing

Beaver Court

80,000 Sq Ft

R&D

Manufacturing

Gilroy Road

72,000 Sq Ft

R&D

Manufacturing

Beaver Dam

52,500 Sq Ft

Raw Materials

Analytical Services

Golden West

72,000 Sq Ft

Analytical Services

Packaging

+1 410-584-0001

+1 410-584-0001

+1 410-584-0001

+1 410-584-0001